Education

Starting with elementary school students through graduate school, we offer various programs to increase awareness and knowledge of the latest assistive technologies and increase students' interest in STEM. Most experiences involve hands-on training.

CARRT aims to increase the capacity of engineers, researchers, and practitioners in the rehabilitation engineering and assistive technology field through education and training. CARRT also focuses on developing highly skilled, high wage workforce. The following are courses offered by faculty associated with CARRT. New educational courses in assistive, rehabilitation and robotics technologies are also being developed.

Do you have a project idea for Capstone Design students?

If you have an idea for a Capstone Design project and you would like to send your idea for consideration, please fill the following form and send it to the email shown on the form:

Capstone Design Project Idea Form

--------------------------------------------------------------------------------------------------

Courses

EML 4930/6930 Special Topics: Rehabilitation Engineering

Course Description:

The purpose of this course is to introduce engineering principles and provide a foundation in rehabilitation engineering, a field dedicated to improving the lives of people with disabilities. This course provides an introduction to rehabilitation engineering and assistive technology, an understanding of rehabilitation technology terminology and standards, and an awareness of issues facing engineers, researchers, clinicians, and individuals with disabilities in the design, development and use of rehabilitation and assistive technology.

Course Topics:

- Fundamentals of Rehabilitation Engineering Design

- Biomechanical Analysis of Human Movement

- Universal Design and Accessibility

- Prosthetics and Orthotics

- Wheelchair and Crutch Design

- Wheelchair Safety, Standards and Testing

- Recreational Devices and Vehicles

- Rehabilitation Robotics

- Virtual Reality Rehabilitation

- Functional Electrical Stimulation and Exoskeletons

EML 4551 Mechanical Engineering Capstone Design

Course Description:

This course is required for mechanical engineering undergraduate students. Students take an idea that has potential to help individuals with disabilities and develop the design to prototype phases. They learn about the design process, develop ways to be creative, cultivate teamwork skills, and discover how to ultimately benefit the community. The course gives students the opportunity to work on 'real-world' problems in a structured amount of time. The training that these students receive through this course will strengthen their job prospects.

Course Topics:

- Creativity, Conceptualization, Design Processes, and Design Synthesis

- Engineering Ethics, Social Impact, and Professionalism

- Computer Aided Design

- Lectures: Resumes, Job Interviews, Patents and Licensing, and Entrepreneurship

- Cost Analysis

- Written Communications and Oral Communication

- Evolution of Products based on Need, Function and Technology

- Human Factors in Design

- Engineering Materials, Product Performance and Consumer Product Design

EML 4930/6801 Mechanics and Control of Robot Manipulators

Course Description:

The purpose of this course is to understand the science and engineering of mechanical manipulation and kinematics. The course introduces students to special coordinate frames and 3D transformations. It describes the kinematics and inverse kinematics of robotic manipulators and the velocities/forces affecting their motion. It also introduces students to various ways to generate 3D trajectories and control manipulators in a linear and nonlinear fashion. Matlab programming and simulation is an integrated part of the course.

Course Topics:

- Introduction

- Spatial Descriptions and Transformations

- Manipulator Kinematics

- Inverse Manipulator Kinematics

- Jacobian: Velocities and Static Forces

- Manipulator Dynamics

- Trajectory Generation

- Manipulator Mechanism Design

- Linear/Nonlinear Control of Manipulators

- Robot Programming and Simulation

EML 4593/6593 Haptics

Course Description:

This class will introduce the field of haptics as it relates to creating touch feedback in simulated and virtual environments. Students will learn about human haptic sensing and control, haptic interfaces (tactile and force), teleoperation, haptic rendering, modeling, control and stability of virtual environments, and how to program these implementations on a SensAble Phantom Omni (shown on the top right).

The Haptics class serves as an elective for undergraduate or graduate students interested in robotics, biomechanics, and related fields.

Course Topics:

- Control/stability of feedback in virtual environments and robotic systems

- Haptic Interfaces

- Teleoperation Control Systems

- Haptic Rendering

- Modeling

- Human Sensory Capabilities

- Statistics

- Programming

CIS 4930 Introduction to Robotics

Course Description:

This course is an introduction to robotics. Students will learn the fundamentals of robotics, algorithms for designing robot motion and examples of robotic systems.

Course Topics:

- Basics of robotics and linear algebra

- Matlab

- Homogenous transformations

- Kinematic chains

- DH convention

- Forward and inverse kinematics

- Angular velocity

- Jacobian matrix

- Motion planning

- Sensors and actuators

- Mobile robots

BME 4440 Introduction to Bioastronautics

Course Description:

The Introduction to Bioastronautics course includes the study and the support of life in space. Bioastronautics is a specialty area in space research that promotes interdisciplinary collaborations in multiple areas of engineering as well as in other scientific areas such as chemistry, biology, medicine, rehabilitation, and psychology. This course will discuss the following topics: the space environment, impacts of microgravity on human physiology, human factors in spacecraft design, astronaut training, the basics of life support system design and countermeasures and mission logistics and planning. The course will include listening to guest speakers from industry, learning about relevant NASA programs accessing resources from nearby Kennedy Space Center, and completing a small design project.

Course Topics:

- Atmosphere

- Radiation environment

- Bone and muscle loss in microgravity

- Neurovestibular adaptations

- Cardiovascular system adaptations

- Cellular response to microgravity

- Motion sickness prevention and treatment

- Crew psychology

- Countermeasures

- Extravehicular Mobility Unit

- International Space Station

- Mission planning

Capstone Projects

Wheelchair Modifications

Off-Road Manual Wheelchair

Peter Falvo, Richard Haynes, Jason Smith, Alejandra Vega, and Jean Pierre Zola

An off-road manual wheelchair was designed for an active 95th percentile male that would be able to ride around a city/town environment but not be limited to riding only on the sidewalks. Some of the characteristics that were taken into consideration during the design process were: compactness, propulsion, and ease of use. The design was kept simple while trying to achieve the multiple design considerations. The main feature of the wheelchair is a four bar mechanism that aids in wheelchair propulsion while the arm motion of the user follows an elliptical pattern. This elliptical motion is more comfortable for the user than a circular motion that a regular crank mechanism would provide.

A four bar crank-rocker mechanism is used for propulsion. The crank-rocker mechanism allows the user follow an elliptical pattern when pedaling rather than the circular motion of the solitary crank system. The elliptical pattern allows for a smoother trajectory for the arm therefore making the propulsion mechanism more natural and easier for the user. This elliptical pattern also maximizes the range of motion that the user's arm travels compared to the range of motion of the solitary crank system.

Composite Wheelchair Design

Kimberlee Fraser, Christopher Nelson, Sean Meibers, Nathan Shinn, and Tahiem Williams

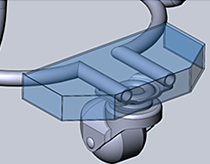

In this paper we describe an innovative design for a manually powered wheelchair. While much has changed in the assistive device industry, wheelchair designs have remained stagnant. Users are confronted by an assortment of heavy, institutionally styled wheelchairs. By utilizing the unique properties of carbon fiber we were able to design a lightweight, modern wheelchair for an active adult user. Further improving on existing designs, we expanded our project to include a complete rework of wheelchair wheels. Our resulting spoke-less wheel and single front spherical caster decrease the visual weight of the chair while also improving mobility. The final weight of our design is 22 pounds, mostly due to the spoke-less wheels. Our frame weighs less than three pounds.

The frame of our final design is best described as organic; lacking some of the right angles and sharp edges of current wheelchairs, particularly where structural components meet. Whereas traditional tubular frames are generally joined by welding together straight pieces of steel or aluminum at angles that create sharp transitions, our frame employs large radius fillets between structural elements. This results in a striking aesthetic while simultaneously reducing stress concentrations. Every joint on the design would have a filleted radius because that is how carbon fiber is manufactured. These gradual transitions between the components give our design a more flowing visual impression and imply that the wheelchair is made from a single continuous piece of material. In turn, this effectively highlights our choice of carbon fiber as the primary material of the wheelchair's construction.

In addition to its graceful form, our frame is designed to maximize maneuverability with an efficient and compact footprint. Despite the current ADA accessibility requirements for architecture, wheelchair users can find themselves in spaces that may outdate these requirements and can be more restrictive: narrow hallways, small door frames, and high profile thresholds that were once common building standards. Our frame combines a narrow width with a shorter overall length, and along with the forward caster wheel this enables users the freedom to navigate tight spaces more easily.

The spoke-less wheel is the second major component of our composite wheelchair design. It continued the effort to design a wheelchair that stood out from the rest of the industry. In standard wheelchairs, along with bicycles and automobiles, the outer tire of a wheel wraps around an inner frame which then connects to a central axle attached to the frame. In designing a spoke-less wheel an alternative method is needed. There are three main components of the spoke-less wheel: the inner frame, the outer wheel, and bearings. An outer moving wheel runs around a second circular inner frame. The inner frame would only be slightly smaller than the outer wheel, fitting inside and partially enclosed by the wheel. This would be accomplished by manufacturing the outer wheel in two parts that would then be assembled around the inner frame and locked into place through several bolts. The inner frame would then connect to the main body of wheel chair through three brackets. Between the inner frame and outer wheel would be a series of bearing surfaces. Currently these bearing series are 40 alternating bronze barrel bearings. They contact the wheel on angled surfaces, providing the bearing support while acting to keep the wheel centered into the frame.

The last major component of the composite wheel chair is the single caster wheel. Caster wheels provide full rotation for the user and allow them to get around with little effort. The bottom of the caster wheel will be made flat to increase the contact area, giving the user more control and stability. The flat wheel also prevents the user from getting stuck in small and large cracks, and it allows the wheelchair to operate on different terrains. Caster wheels are durable, easily replaceable and can withstand a large amount of weight. Although the caster wheels will improve the mobility, they may not be repairable.

Off-Road Hovercraft

Gerald Daun, Olga Ramos, Chris Hages, Roberto Fung, and Thomas Driscoll

The goal of this project was to create an off road vehicle to help extend the mobility of persons with disabilities. Currently there are several options available to the public such as the Super Four wheelchair and the Tank tread chair, however, these designs all revolve around wheeled or tracked vehicles. The design chosen needed to be one that would be innovative and original and have the potential to exceed the capabilities of the current off-road wheelchairs, while possibly accessing other markets besides just the disabled community. One design trait that all current off-road wheelchairs have in common is the wheel or track based drive train. To differentiate the design from potential competition a hovercraft, or Air Cushioned Vehicle (ACV), was selected for development.

The final design decided on was a turbine powered hovercraft that would be capable of maneuvering on flat or rough terrain and water. This design would focus primarily upon the base of the craft to ensure stability and adequate space and a custom designed three stage turbine. The outside base was created out of Hypalon®, a flexible synthetic rubber material that has proven itself to have excellent air holding capabilities and oil resistance. The inside of the base would then be covered in fiberglass to make it airtight and flexible. The design incorporated a dual engine system. One would be used to lift the craft by forcing high pressure air under the vehicle and the other would drive the turbine that would provide the means of propulsion.

Off-Road Beach Vehicle

Andrew Abney, Kathleen Boland, Garrett Gregory, and Brandon Halbert

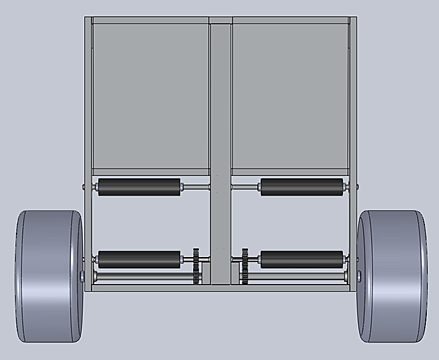

Our project aims to provide extended mobility for those confined to wheelchairs by allowing them to extend their range to off road surfaces. We designed this product with the specific audience of beach side resorts. Our design utilizes a platform that a user's wheelchair mounts to, allowing multiple wheelchairs to fit. This design uses corrosion resistant materials and a drive train connected to a roller that the wheelchair sits on to provide the user with familiar controls. Each side of the vehicle is independent of the other allowing for full independent steering.

The specific design criteria laid out for the project is listed below, the vehicle must: support a load of 450 pounds, utilizes an off-road surface interface (tires/tracks), utilizes little if any extra force, ensure independent steering, withstand a beachside environment, have the widest wheelbase possible, have a specific commercial use. The dominating criteria were the load allowable and the ability to withstand the elements encountered during beachside use.

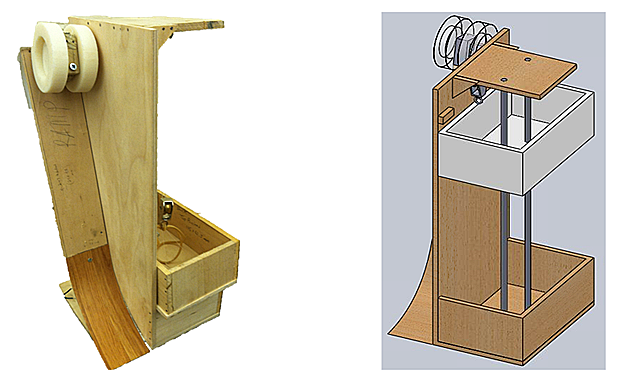

Design and Implementation of a Portable Mobility Lift for Transportation Vehicles

Benjamin Bergin, James Pierce, and Randell Stokes

Wheelchair bound individuals are at a distinct disadvantage compared to able bodied individuals when it comes to vehicular choice. The authors worked to help alleviate this handicap by designing a rugged, lightweight lifting device that will enable individuals be to lifted into a vehicle with no modification to the vehicle. We accomplished this by using a pulley and cable drive system utilizing a winch and worm gear. With an overall final weight of around 70lbs, any able bodied individual should be able to fulfill the role of a caregiver in assisting the entry and egress of a wheelchair into a vehicle.

Our design utilized a lightweight, aluminum frame with a hand crank mechanism to raise and lower an occupant through the use of a cable and pulley system. Our design is also light enough to allow a caregiver to lift and store the mechanism in the vehicle for easy, portable storage. The choice to use a worm gear drive system in conjunction with a pulley helps to solve issues that arise by using manual power. It allows us to gear the system with a very high gear ratio allowing relatively little input from the caretaker to lift the platform. It also allows for a very compact gear system.

Off-Road Manual Wheelchair

Alexander Keever, Andrey Kharitonenko, Justin Harrison, Oscar Levy, and Jacob Lashley

The task of this project was to design an off road mobility device that could be operated by a user with limited lower body function. The device needed to be manually driven by the user. In order to limit the scope of this task, we chose to focus on a beach environment. This environment is assumed to have a relatively flat terrain mostly made of loose sand.

The device was built with several features: it will be completely manually driven, it will not require much more space than a standard wheelchair, and it will not require any assistance. Our approach is motivated by the universal desire of people to explore their surroundings and not be reliant on others.

The final design is a self-propelled outdoor terrain vehicle designed for optimal use for a person with a lower extremity handicap. It incorporates the use of a bench-press power plant that transfers power to the wheels via crank rocker. Two crank rockers are used to propel the vehicle with each rocker independent from the other. This allows the user to turn by providing more power to one side allowing for exceptional mobility especially at slow speeds. The bench press motion is advantageous in that it exploits more muscle groups than with a standard wheelchair. In a standard wheelchair, a user must rely heavily on the small muscles of the arms and shoulders. In the final design, however, the larger chest and shoulder muscles are used which allow the user to prolong their experience over rough terrain.

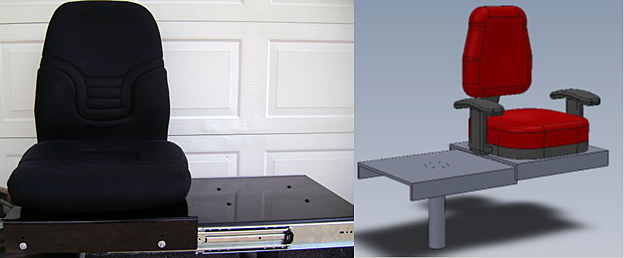

Wheelchair Sliding Seat

Nicole Birchell, Christian Giron, Daniel McConnell, Cory Nation, and Jonathan Todd

There are currently an estimated 1.6 million Americans who use a wheelchair on a daily basis. Many tasks require users to transfer from their wheelchair to another area, such as a bed or vehicle. Essentially they need an extension of their chair to help them move. Currently the most popular method is sliding on a wooden board. This accessory must be kept either with the user or at the location of use. This extra bulk is considered a burden by those in wheelchairs and causes interference with their everyday life. The desire for a wider range of accessible area with using only a wheelchair drives the motivation for this project.

This project seeks to create a permanent fixture for a wheelchair which extends its usable range without moving the base of the chair. The primary goal is to have a permanent seat slide away from the base of the chair. If the seat can remain attached to the base yet extend into a nearby area, it could eliminate the need for a wooden board.

Another important feature which must be developed is adjustment at the end of extension. Once the chair has been extended into a more useful range, the ability to adjust the position of the user is crucial. Usage would be severely limited if there is no way to orient the user into an acceptable position. Also, if there is no adjustment at the end of the seat, then the user may rely of the movement of the base for adjustment. This is unsafe and also defeats much of the purpose of this design.

To operate the prototype sliding seat, the user needs to maneuver the wheelchair to a parallel position at least 20 inches away from the desired surface. Then the user simply unlatches the sliding mechanism and slides over to the desired surface. To leave the surface, just do the reverse. It is understandable that some places are more difficult to maneuver an electric wheelchair to a position so the sliding seat can be utilized correctly. Therefore, we have introduced the feature of a turntable to allow the maximum angle allowance. This may come in handy in some rooms that are smaller or narrower.

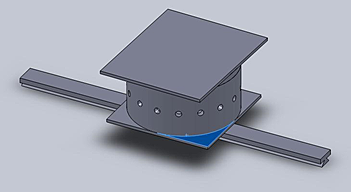

Rotational and Sliding Seat Mechanism

Scott Padilla, Kyle Hanrahan, Mark Marchese, Nick Stephenson, and Igor Markovic

Most power wheelchair seats are fixed to the frame and cannot be easily removed. Our group decided to create a wheel chair base that would assist handicapped persons in their daily lives. Having a seat that slides with the user to a toilet or other surface would reduce the need for expensive lifts. The design parameter of the project were that the unit should be self-contained, be able to support up to five hundred pounds, the seat of the mechanism should be able to slide left or right, and that the unit should have one hundred and eighty degrees of rotational motion. Each one of these criteria was inspired by a different need we thought the user of this mechanism might have.

The final design chosen consists of three main parts. First is the aluminum rail with a mounted pillow block that is used to move the mechanism left and right from its original central position. Second is the rotational base. Third is the base, on which the seat of the wheel chair would be mounted to. The aluminum rail and pillow block are the two most integral parts of the mechanism, which control the twenty five inches of motion, from complete left to complete right, of the design. Attention was given towards eliminating the possibility of tipping when the chair is in the full left or right position. This is what led to only allowing twelve and a half inches of movement to the left or right of the center position of the chair.

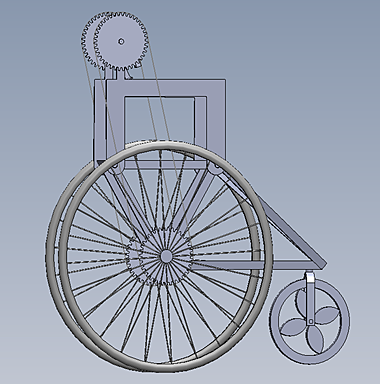

Design of an Off Road Manual Wheelchair

Ernesto M Cruz, Jose Lorenzo, Manikaran chandok, Mohammed Almaghrabi, and Yagneshkumar Patel

The purpose of this project is to design an affordable and manageable off road wheel chair. This wheelchair is supposed to take individuals to places a regular wheel chair cannot. Light and strong materials, capable of supporting more than 300 pounds, were used in the fabrication of the prototype. A strong gear mechanism was used in the design to make the ride easier for the rider.

The prototype for the off road wheelchair consists of a major subsystem and few additional parts. The power system consists of two sets of gears and pedals which provide the mechanical advantage necessary for a user to move about comfortably in the wheelchair on any terrain. The transmission system consists of two brake linkages mounted on the rims which assist in stopping and stabilizing the wheelchair during vertical descent and ascent. The oversized wheels create more surface area for traction.

Manual Off-Road Wheelchair

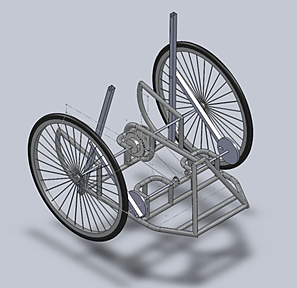

Felipe Cuesta, Rene Goderich, Daniel Miller, and Razi Ullah

Our mission was to design and construct an off-road wheelchair to be used by a disabled person with strong upper body muscles. We decided that our vehicle should function properly on the beach as well as on a sidewalk. The last requirement that our team planned to accomplish is to design the wheelchair to be modular in nature. This would allow for the user to board our wheelchair via a ramp and would eliminate the step of switching wheelchairs all together.

The off-road wheelchair design is actually a modular attachment to a standard wheel chair which allows the user to mount and dismount via a ramp in order to travel on difficult terrain such as dirt and sand. The design of this wheelchair allows for the user to propel the vehicle using two independent levers. Using just one lever, the user can turn in the opposite direction which allows for easy steering. The rider's wheelchair is secured via a ratcheting tie-down which allows for quick maneuvering with minimal effects to the rider.

The construction of our prototype was not as fruitful as we had hoped. Our design turned out to be too tall and shifted the center of gravity of the object higher which means it has a higher chance of tipping over when turning. During the welding process, we welded the steel tubing to the platform and the steel tubing to the bike frames. This caused the wheelchair to become wobbly and slightly unbalanced, but still operational. The tires are still too thin to operate efficiently in a sandy environment. Protective shielding has not been installed to protect the gears from the sand and this will accelerate corrosion to the product. Because of its bulky size, it cannot navigate well in cluttered environments.

Having produced a functional prototype, it can be considered at least somewhat effective solely in this regard. However, it additionally provides a test platform from which to experimentally evaluate the validity of the concept and thereby suggest improvements. This is a full-scale functional prototype rather than a scale model and as such provides full-scale functionality. While this first attempt is somewhat crude, it admirably embodies the design concept especially when taking into consideration the resources available for its construction. Moreover, the utilization of pre-manufactured systems (the bicycle parts) eliminates some uncertainly about the reliability of the drive system by relying on a proven design.

Off-Road Manual Wheelchair

Vincent Shatlock, Ryan Uchida, and Joseph Wirth

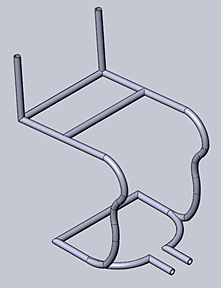

The challenge in this project was to create a new design for a manually-powered wheelchair capable of traversing off-road terrain. The goal was to create a working prototype of a design that could be operated with only the use of the user's arms. Rather than basing the design on currently existing wheelchair models, the goal was to create a product that did not resemble a traditional wheelchair. To accomplish this, the traditional straight-back, four-wheeled idea of a wheelchair was abandoned, and the design was based primarily on functionality and aesthetics. The resulting product has three wheels, a steel tube frame, two independent lever-crank-chain drives that are capable of freewheeling, and hand-operated cable brakes. Because of time and budget constraints, the scope of this project was limited to leave out some functions, such as a multiple gear system and the ability to drive the wheelchair in reverse. However, the first run prototype is fully functional, and is a design that can be used by anyone, with or without disabilities.

The final design is a three-wheeled chair; two 26" drive wheels in the front, and a single 8" wheel in the rear. Bicycle wheels with off-road tires were used to drive the wheelchair and a lawnmower wheel was used for the rear, to increase traction and stability on the intended terrain. The welded frame was constructed of 1" square tubing and 1.25" round tubing, all steel.

The original prototype that the project was based on required two revisions to accomplish the desired result. While conducting road trials on the original prototype, it was determined that the turning of the off-road wheelchair could not be controlled. The second prototype used the original frame but the fork was swapped out for a fork that was heated to red hot and bent. This bent fork was employed to not only increase the distance from the center of mass, but to change the angle of the axis of rotation. A reduced diameter rear wheel was also imployed. The combination of the bent fork and the smaller diameter rear wheel was successful. The wheelchair is now able to perform as initially intended.

Others

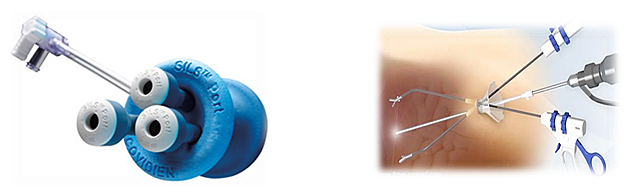

Minimally Invasive Medical Device

Brandon Clark, Joel Cooper, Shaun DeSouza, Jon Kippert, Dennis Walker

The surgical industry is always in need of new technology. Recently, there has been a push for the innovation of smaller devices in order to reduce the risks associated with surgery. In this project the authors developed a new device that requires a smaller incision than any of the devices on the market today. This new device is cost effective, easy to manufacture and meets the requirements specified by the surgeon.

The final design of our initial prototype consisted of our compliant gripping mechanism, a hypodermic tube that houses the gripping mechanism, and a handle that manipulates the gripping mechanism utilizing a slider.

There are three main components to the handle, a fixed base, a slider, and a probing shaft. Attached to the base of the handle is the trigger which translates the slider in the base housing. To secure these components together, we used a spring pin and a sleeve screw. The shaft is a 14 gauge stainless steel hypodermic tube with a wall thickness of 0.25mm. The outer diameter of the shaft is 2mm which is a major design requirement for our product. This particular dimension allows the surgeon the ability to insert and remove the device without the need to suture the hole created. This reduces the risk of infection, post-operative hernias, and scarring.

The advantages of our design are the small diameter probing shaft and its high force to size ratio. The wire used to fabricate our device is very thin but it still has the ability to remain straight in long lengths. This is an issue we had to design around because current devices on the market were kept in a range on lengths suited to the need of surgeons. The main advantage of our design is that it reduces scarring, infection and post-operative hernias. The main disadvantage of our design is the current movement of the gripper. Surgeons view the procedure on a screen that offers no depth perception which means that they often miss the organ they intend to grip. When the trigger is manipulated on our device, the gripper retracts away from its target. This is currently an issue with existing medical gripping devices on the market. Our second prototype device will solve this existing design problem.

H2Go Car: Water-Powered Propulsion

Matthew Harrison, Megan Malek, Vance Brendan Perry, Michelle Smith, and Kevin Steckbauer

Rainwater is a clean, untapped energy source that can be utilized. For the purposes of creativity, and problem solving in the energy industry ASME has developed annual student competitions for upcoming engineers. The student competition for 2011 involved powering a vehicle with 1 liter of water dropped at a height of 1 meter. With specific tolerances, not using stored energy, and following clarifications as outlined by the organization, our team built a water carrying device and a 2-wheeled vehicle.

The H2Go car uses energy from falling rainwater to propel a car a certain distance. Specifically, teams had to create a mechanism that could create kinetic energy from the potential energy of one liter of water one meter high. The distance that the car traveled was the measure of success.

We had some difficulty with the original prototype. However, with modifications, we were able to have a better functioning device. The car was meant to be able to function on a multitude of surfaces, including linoleum and indoor/outdoor carpeting. The best runs of our prototype recorded the car at a maximum traveling distance of 58 feet on linoleum and 26 feet on the indoor/outdoor carpeting.

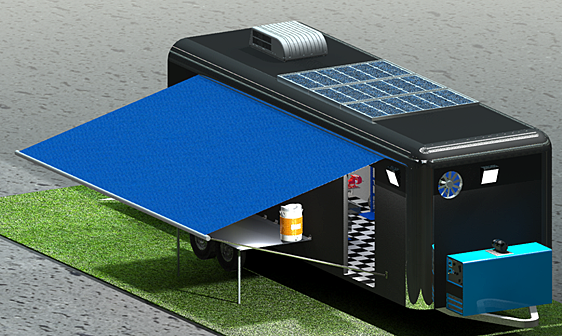

The Design of a Modular, Mobile, Customizable Work Platform

Drew Carpenter, Justin Dodson, Sean Motta, and Adam Zimandy

This project dealt with the design of a modular, mobile, customizable work platform that will be used by professionals in the field. We made a modest attempt to replicate the natural work environment found in a larger, stand-alone, professional work shop. Several constraints were strictly followed. The design had to be street legal, have a total workspace greater than 4 feet by 8 feet, have the ability to work in inclement weather, and have theft prevention capabilities. Various possible solutions were looked at. With strict use of a decision matrix, we were able to determine that the best possible solution would be an enclosed trailer.

In order to transport a sufficient amount of tools and stock materials a large platform is needed but it needs to remain street legal. For the final design, we chose an 8 foot by 20 foot enclosed Horton trailer. Since most contractors usually work at construction sites, the mobile workstation must be able to navigate on various terrains. It is also important to protect the tools and the contractor from inclement weather. As such a secondary design constraint is to include a covered work area.

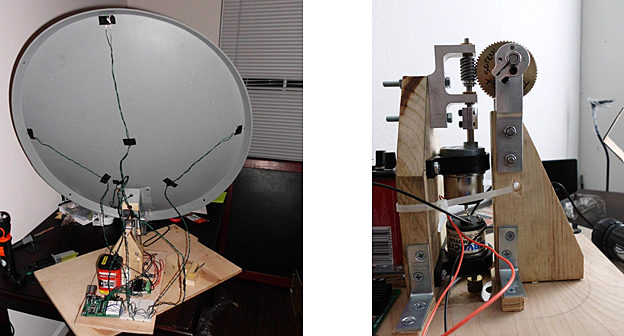

Solar Tracking Dish

Paul Clark, Brandon Marks, and Marc Ransome

This project produced a working prototype of a solar tracking dish system utilizing a microcontroller. The working prototype successfully tracked the movement of the sun throughout the day. The system utilizes a microcontroller in conjunction with a set of LEDs to track the position of the sun throughout the day. This system needed to be able to capture the sun's light with a repurposed satellite dish and direct its energy to the focal point. We had to design the appropriate gearing system and motors to use as little energy as possible while being able to properly move the dish, thus resulting in a net gain of energy.

To transmit motion to the dish we decided to use two high torque low rpm gear motors in combination with a planetary gear arrangement for horizontal adjustments about a vertical axis and a worm gear for vertical adjustments about a horizontal axis. The system was placed on a swiveling base in which the sun gear for horizontal movement was fixed to the base and the planetary gear was powered by a motor and would rotate around the fixed gear in turn causing the platform to rotate around the center of the base.

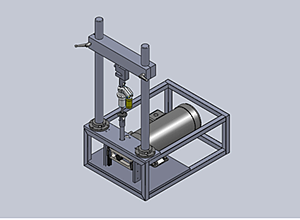

Damper Dynamometer

Carl-Serge Franck, Kyle Jeffries, and Eric Petersen

In order to understand the importance of a damper dynamometer, one must first look into dampers. A damper, or shock absorber, is a device that absorbs and dissipates kinetic energy. Pneumatic and hydraulic dampers are the norm in the automotive industry, taking the form of a cylinder with a sliding piston inside. The cylinder is filled with a fluid, typically hydraulic fluid or air. For the main part, the energy is converted to heat inside the viscous fluid. Dampers play a major role in automotive applications, including racing. With such a wide range of functions, testing of these devices is a must. Currently, dampers are tested using specialized dynamometers which run through its full range of motion. At high speeds, a car may often take damage from bumps which ruin the entire frame of the vehicle, rendering it useless. Dampers also aide in traction as they absorb those bumps which would create lift off from the road.

With that said, outsourcing the testing is very expensive. So, the goal of this project was to design a dynamometer to eliminate the cost of sending the dampers to a company each time testing is required. The dynamometer is also a low-cost alternative to what is out on the market right now. With the design at hand, the estimated cost to build the dynamometer is $1,822.58. This is a big drop off from similar commercial items in the market which cost in excess of $10,000.

The damper dynamometer intended to produce force vs. velocity plots of dampers for Formula SAE and Baja projects at the University of South Florida. The damper dynamometer allows the user to attach a damper up to 14" long to the apparatus and select a testing stroke length of 1.5, 2, 3, or 4 inches. The machine is set to the desired piston velocity and data is collected. This data allows the engineer to tune the damper's characteristics in a measured way. The unit utilizes a 2 horsepower motor that drives a scotch yoke mechanism. Data is collected via a Hall Effect sensor on the crank wheel and a load cell at the top of the apparatus. The unit utilizes a small footprint of only 22x26 inches which allows the engineers to transport the equipment with them to test various dampers on the fly. The machine is also very versatile with major wear items being easily field replaceable and when required the unit is upgradable so that no job is too big or too small.

Community Outreach

CARRT provides mentoring service program for primary education K-12 students and teachers to enter into local and international technology competitions. CARRT personnel conduct laboratory tours, speak to local elementary, middle and high schools, and work with community philanthropic partners.

Girl Scout Engineering Camp:

- Hands on Haptics demonstrations

- Lego Education NXT robotics kits donated

- Tours of CARRT labs

- Encourage careers in engineering and rehabilitation

Robles Elementary School Visits:

- Tours of CARRT labs

- Demonstrations

- Discussion about physical rehabilitation

- Introduction to Haptics

Tampa Prep Presentations:

- CARRT faculty lectures for 10th grade Introduction to Engineering Coures

- CARRT faculty present and mentor high school and middle school robotics clubs

- Demonstration Kinect for Windows and wearable inertial sensors

- Have lunch and discussions with students interested in STEM

Museum of Science and Industry (MOSI):

- Participate in Idea Faire, two day celebration of human creativity and innovation featuring a convergence of robotics, video gaming, science, engineering and makers

- Consult for MOSI's Idea Zone, a "do-it-yourself" laboratory with an open ended platform to allow students of all ages to explore, learn and have fun

USF's Engineering Expo

- CARRT tours and display tables during Engineering Expo, a free event for K-12 to learn about engineering

- CARRT students volunteer during interactive, educational shows and hands on exhibits

CARRT faculty serves as judges for student contests

- Hillsborough Regional Science & Engineering Fair

- State Science and Engineering Fair of Florida

- USF Undergraduate Symposium

- USF College of Engineering Research Day

Learn More

"Center for Assistive, Rehabilitation & Robotics Technologies"

Research - Education - Service